Cream Insulation for Exterior Walls: Navigating Different Siding Types in Michigan's Lower Peninsula

In the heart of Michigan's Lower Peninsula, ensuring an energy-efficient home is a priority for residents. Exterior wall insulation plays a crucial role in this, and Cream Insulation stands out as a top-tier solution. For homeowners concerned about cold, drafty walls, or those expensive heating bills, understanding the installation process becomes essential. Let's delve deeper into how Cream Insulation interacts with various siding types, providing optimal insulation without compromising aesthetics.

1. Vinyl and Aluminum Siding Insulation:

Vinyl and aluminum sidings are staples in many homes. Here's how the process unfolds:

- Detach a segment of the siding.

- Drill a 2 ½-inch hole in each stud cavity.

- Insert a probe to gauge the cavity's depth and obstructions.

- Inject Cream Insulation from the top to bottom, ensuring complete coverage.

- In case of blockages, additional holes are made to guarantee a fully insulated cavity.

- Post-insulation, holes are sealed, and the siding is carefully repositioned.

- The vicinity is then cleaned to restore its original state.

2. Slate Tile Siding Insulation:

Houses with slate tiles follow a procedure akin to vinyl or aluminum siding:

- Crack tile to drill through.

- Usually a messy process and tiles are usually damaged.

- Create entry points in the cavity for the insulation.

- Administer Cream Insulation.

- Seal the holes and restore the tiles as best we can.

3. Brick Wall Insulation:

Brick exteriors require a meticulous approach:

- Drill 3/4-inch holes into the mortar, targeting the top, middle, and bottom of the wall cavity.

- Initiate the insulation process from the top, proceeding downwards.

- Post insulation, debris is cleared.

- The drilled holes are refilled using a specially prepared mortar blend.

4. Stucco Siding Insulation:

Stucco exteriors mirror the method used for brick walls. The drilled holes are subsequently sealed with a matching mortar mix.

5. Wood Siding Insulation:

Lap boards or cedar shake sidings vary in approach:

- Based on the wood's condition, either the siding is removed or holes are drilled directly.

- Cream Insulation is injected, covering the entire cavity.

- Holes are then sealed using tapered pinewood plugs.

For homes featuring T1-11 wood siding, direct drilling is the preferred method, as this siding cannot be easily removed.

6. Vertical Metal Siding Insulation:

Insulating homes with vertical metal siding is distinct:

- Drill a 1 ½-inch hole for insulation injection.

- Following complete insulation, holes are plugged using matching caps and sealed with caulk, ensuring the siding remains undented.

7. Hardie Board Siding Insulation:

Hardie board sidings demand precision:

- Gently lift the board without damaging the nails.

- Remove any caulk and proceed with Cream Insulation.

- Once insulated, reinstall the hardie board, either using the existing nail holes or crafting new ones if necessary.

- Finally, re-caulk around the siding for a seamless finish.

- Sometimes we have to drill holes into the siding as it cannot be removed.

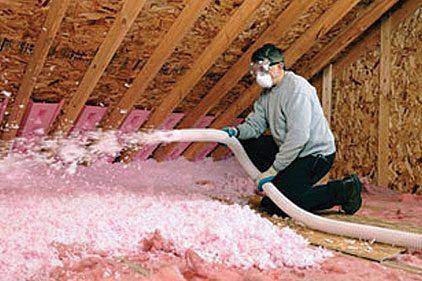

8. Insulating from the Inside:

In certain instances, insulating from the interior is viable:

- Drill a 2 ½-inch hole and gauge the cavity.

- Inject Cream Insulation and cover the hole with a rough patch, leaving the final finishing to the homeowner's discretion.

For basement walls made of concrete blocks, Cream Insulation can be directly sprayed or injected into the block cores.

A Closing Thought:

Michigan's Lower Peninsula residents can now navigate the world of exterior wall insulation with ease. With Cream Insulation, the challenge of cold drafts becomes a distant memory, ensuring a cozy living environment. Concerned about existing fiberglass in your walls? No worries. Older fiberglass installations can remain intact, as Cream Insulation compresses and envelops it, creating a robust barrier. Schedule an estimate here -